This standard is adopted as regulation in all 50 states and is the benchmark for safe electrical design, installation, and inspection to protect people and property from electrical hazards. In addition to the dimensions of depth shown in table 2340.16, the width of the workspace in front of the electric equipment shall not be less than the width of the equipment or 30 inches, whichever is greater. Today we show you how to map out and label your electrical panel, also called the fuse panel, or fuse box. At its core, ul 508a sets parameters for the design, control, and use of industrial control panels intended for general use within the industry. Nec 2017 introduced the new first level subdivision 110.16 (b) service equipment.

electrical equipment, such as switchboards, switchgear, panelboards, industrial control panels, and motor control centers that is in other than dwelling units and is likely to require examination, adjustment, servicing or maintenance while energized, shall be field marked to warn qualified persons of.

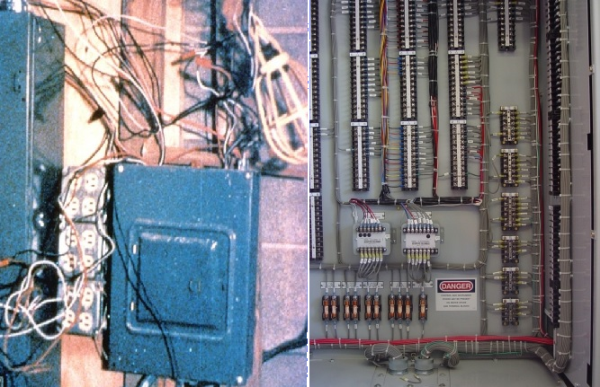

If missing panel mfr label, different comment. The inspector recommends that a circuit label be installed by a qualified electrical contractor.". 110.16, arc flash hazard warning: In all cases, the workspace shall be adequate to permit at least a 90 degree opening of equipment doors or hinged panels. Upgrading to the best 200 amp breaker box is not only risky in many aspects, but it's also expensive. In addition to the dimensions of depth shown in table 2340.16, the width of the workspace in front of the electric equipment shall not be less than the width of the equipment or 30 inches, whichever is greater. The full edition is available here for purchase, but let's take a look at the major points to keep in mind. The.gov means it's official.federal government websites often end in.gov or.mil. This article explains how to estimate the electrical service size, ampacity rating, (or "electrical power" Control panel builders produce control panel labels tags and. Help to ensure your workplace remains osha compliant with our large selection of labels. Typically, the label is placed outside the panel or enclosure door. Let's all do our part in ensuring electrical equipment is properly identified, and, by all means, keep electrical safety at the forefront of our minds.

Industrial control panel shop program. Or "service amps") at a building by visual examination of the electrical service panel, main switch, and other details. Let's all do our part in ensuring electrical equipment is properly identified, and, by all means, keep electrical safety at the forefront of our minds. The ul 508a panel shop program provides certification for canadian and u.s. Tracing circuits and labeling an existing panel is a task that is best done with two people and could take hours.

A directory isn't required where all pv system disconnecting means are grouped at the service disconnecting means.

Labeling a new electrical panel only takes a few minutes. Typically, the label is placed outside the panel or enclosure door. Any business with an electrical panel on its property can use these signs to help promote safety. Or "service amps") at a building by visual examination of the electrical service panel, main switch, and other details. Ppe category from 1 to 4. Find out what an electrical panel or load center in the home does and why it is critical to your safety. A complete directory helps to ensure the safe operation of the electrical system, especially in an emergency. This document also addressed the question of how to label devices that were subject to protection under a selectable maintenance settings scheme. A directory isn't required where all pv system disconnecting means are grouped at the service disconnecting means. Find out the answer from an electrical inspector. Upgrading to the best 200 amp breaker box is not only risky in many aspects, but it's also expensive. But, you are not allowed to have ppe category (5c) with incident energy (5a) or 5b minimum ppe rating (5b). Osha's standard for general electrical requirements (29 cfr 1910.303) includes a section for establishing and maintaining space around electrical panels and other systems that require servicing, adjustments, or maintenance while energized.

A complete directory helps to ensure the safe operation of the electrical system, especially in an emergency. Osha and nfpa 70e require electrical panels, equipment, and conductors all be clearly labeled. National electrical code (nec 2011). electrical load calculations will be required, and the panel manufacturer must authorizesuch modification. Labeling that can survive these deteriorating agents should be used to warn about workplace substances that should not come in contact with electrical equipment.you can fulfill your labeling requirements and create custom electrical labels with duralabel industrial labeling kits.

Typically, the label is placed outside the panel or enclosure door.

The 2017 edition of the nec has introduced some new labeling requirements for industrial machinery control panels that bakers should be aware of. Ppe category from 1 to 4. electrical panel stickers ship fast. 408.4 (b) field identification required. In some cases, companies choose to put the label inside the door to protect it from harsh. Quickly identify electrical hazards of equipment and machinery with labelmaster's electrical voltage labels. 409.110(3), 440.4(b), and 670.3(a)(4) reference the labeling requirements in which "sccr" This article explains how to estimate the electrical service size, ampacity rating, (or "electrical power" Solar system labels and signs. Arc flash hazard warning label as required by 110.16 (a) of nec 2017. electrical equipment, such as switchboards, switchgear, panelboards, industrial control panels, and motor control centers that is in other than dwelling units and is likely to require examination, adjustment, servicing or maintenance while energized, shall be field marked to warn qualified persons of. The ul 508a panel shop program provides certification for canadian and u.s. If missing panel mfr label, different comment.

Required Labels On Electrical Panels - Arc Flash Labels Osha Compliant : If you need your electric panel labeled or if you want electrical panel upgrades, contact your local mr.. An often overlooked aspect of electrical safety training is labeling. This standard is adopted as regulation in all 50 states and is the benchmark for safe electrical design, installation, and inspection to protect people and property from electrical hazards. 409.110(3), 440.4(b), and 670.3(a)(4) reference the labeling requirements in which "sccr" Ppe category from 1 to 4. electrical panel labeling best practices.